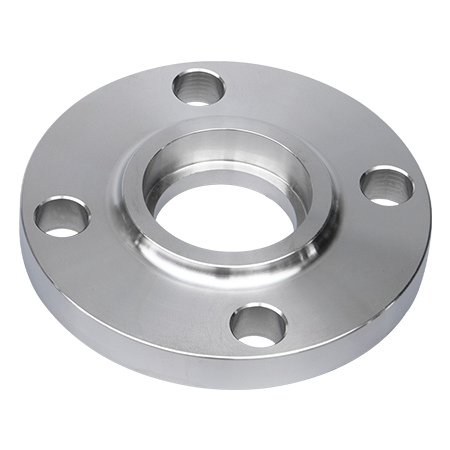

Muffenschweißflansch

Zertifizierungsstandards

Diese Flansche sind für hervorragende Dichtheit und Festigkeit ausgelegt und eignen sich ideal für den Einsatz in anspruchsvollen Branchen wie Erdöl, chemische Verarbeitung, Erdgas und Kraftwerke.

GB/T9119-2010

HG/T20592-2009

HG/T20615-2009

DIN

ASME

BS

JIS

Material:

304:F304 S30408 S30408II S30408III S30400

304L:S30403 S30403II 30403 30403II

316L:31603 31603II 31603III

2507(F53)

2205(F51)

TP310S(06Cr5Ni20)

TP321(06Cr18Ni11)

S22053III=2205III

T321-32168=321

Schweißmuffenflansche werden für kleine Rohrleitungen und Hochdruckleitungen verwendet, die keine hochkorrosiven Flüssigkeiten übertragen, da diese Flansche im Spaltbereich zwischen dem Rohrende und der Muffenschulter korrodieren.

///KLASSE 150///

| Nominale Größe | Außendurchmesser des Stahlrohrs A | Flansch-Außendurchmesser D | Größe der Verbindung | Flanschdicke C | Flansch-Innendurchmesser B1 | Steckdose | Flanschenhals großes Ende N | Flanschhöhe H | Theoretisches Gewicht Kg | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | Lochkreisdurchmesser der Schraube K | Mutiger Lochdurchmesser L | Bolzenloch Anzahl n(Stück) | B2 | U | |||||||||||

| 15 | 1/2 | 21.3 | 90 | 88.9 | 60.3 | 16 | 15.7 | 4 | 9.6 | 15.5 | 15.7 | 22.5 | 22.4 | 10 | 30 | 14 | 0.42 |

| 20 | 3/4 | 26.9 | 100 | 98.6 | 69.9 | 16 | 15.7 | 4 | 11.2 | 21 | 20.8 | 27.5 | 27.7 | 11 | 38 | 14 | 0.59 |

| 25 | 1 | 33.7 | 110 | 108 | 79.4 | 16 | 15.7 | 4 | 12.7 | 27 | 26.7 | 34.5 | 34.5 | 13 | 49 | 16 | 0.81 |

| 32 | 1 1/4 | 42.4 | 115 | 117.3 | 88.9 | 16 | 15.7 | 4 | 14.3 | 35 | 35.1 | 43.5 | 43.2 | 14 | 59 | 19 | 1.07 |

| 40 | 1 1/2 | 48.3 | 125 | 127 | 98.4 | 16 | 15.7 | 4 | 15.9 | 41 | 40.9 | 49.5 | 49.5 | 16 | 65 | 21 | 1.36 |

| 50 | 2 | 60.3 | 150 | 152.4 | 120.7 | 18 | 19.1 | 4 | 17.5 | 52 | 52.6 | 61.5 | 62 | 17 | 78 | 24 | 2.1 |

| 65 | 2 1/2 | 76.1 | 180 | 177.8 | 139.7 | 18 | 19.1 | 4 | 20.7 | 66 | 62.7 | 77.6 | 74.7 | 19 | 90 | 27 | 3.33 |

| 80 | 3 | 88.9 | 190 | 190.5 | 152.4 | 18 | 19.1 | 4 | 22.3 | 77.5 | 78 | 90.5 | 90.7 | 21 | 108 | 29 | 3.9 |

///KLASSE 300///

| Nominale Größe | Außendurchmesser des Stahlrohrs A | Flansch-Außendurchmesser D | Größe der Verbindung | Flanschdicke C | Flansch-Innendurchmesser B1 | Steckdose | Flanschenhals großes Ende N | Flanschhöhe H | Theoretisches Gewicht Kg | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | Lochkreisdurchmesser der Schraube K | Mutiger Lochdurchmesser L | Bolzenloch Anzahl n(Stück) | B2 | U | |||||||||||

| 15 | ½ | 21.3 | 95 | 88.9 | 66.7 | 16 | 15.7 | 4 | 12.7 | 15.5 | 15.7 | 22.5 | 22.4 | 10 | 38 | 21 | 0.66 |

| 20 | ¾ | 26.9 | 115 | 98.6 | 82.6 | 18 | 15.7 | 4 | 14.3 | 21 | 20.8 | 27.5 | 27.7 | 11 | 48 | 24 | 1.15 |

| 25 | 1 | 33.7 | 125 | 108 | 88.9 | 18 | 15.7 | 4 | 15.9 | 27 | 26.7 | 34.5 | 34.5 | 13 | 54 | 25 | 1.4 |

| 32 | 1 ¼ | 42.4 | 135 | 117.3 | 98.4 | 18 | 15.7 | 4 | 17.5 | 35 | 35.1 | 43.5 | 43.2 | 14 | 64 | 25 | 1.75 |

| 40 | 1 ½ | 48.3 | 155 | 127 | 114.3 | 22 | 15.7 | 4 | 19.1 | 41 | 40.9 | 49.5 | 49.5 | 16 | 70 | 29 | 2.55 |

| 50 | 2 | 60.3 | 165 | 152.4 | 127 | 18 | 19.1 | 8 | 20.7 | 52 | 52.6 | 61.5 | 62 | 17 | 84 | 32 | 2.93 |

| 65 | 2 ½ | 76.1 | 190 | 177.8 | 149.2 | 22 | 19.1 | 8 | 23.9 | 66 | 62.7 | 77.6 | 74.7 | 19 | 100 | 37 | 4.4 |

| 80 | 3 | 88.9 | 210 | 190.5 | 168.3 | 22 | 19.1 | 8 | 27 | 77.5 | 78 | 90.5 | 90.7 | 21 | 117 | 41 | 5.92 |

///KLASSE 600////

| Nominale Größe | Außendurchmesser des Stahlrohrs A | Flansch-Außendurchmesser D | Größe der Verbindung | Flanschdicke C | Flansch-Innendurchmesser B1 | Steckdose | Flanschenhals großes Ende N | Flanschhöhe H | Theoretisches Gewicht Kg | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | Lochkreisdurchmesser der Schraube K | Mutiger Lochdurchmesser L | Bolzenloch Anzahl n(Stück) | B2 | U | ||||||||||

| 15 | 1/2 | 21.3 | 95 | 88.9 | 66.7 | 16 | 15.7 | 4 | 14.3 | &/8211; | 22.5 | 22.4 | 10 | 38 | 22 | 0.76 |

| 20 | 3/4 | 26.9 | 115 | 98.6 | 82.6 | 18 | 15.7 | 4 | 15.9 | &/8211; | 27.5 | 27.7 | 11 | 48 | 25 | 1.29 |

| 25 | 1 | 33.7 | 125 | 108 | 88.9 | 18 | 15.7 | 4 | 17.5 | &/8211; | 34.5 | 34.5 | 13 | 54 | 27 | 1.55 |

| 32 | 1 1/4 | 424 | 135 | 117.3 | 98.4 | 18 | 15.7 | 4 | 20.7 | &/8211; | 43.5 | 43.2 | 14 | 64 | 29 | 2.06 |

| 40 | 1 1/2 | 48.3 | 155 | 127 | 114.3 | 22 | 15.7 | 4 | 22.3 | &/8211; | 49.5 | 49.5 | 16 | 70 | 32 | 3.00 |

| 50 | 2 | 60.3 | 165 | 152.4 | 127 | 18 | 19.1 | 8 | 25.4 | &/8211; | 61.5 | 62 | 17 | 84 | 37 | 3.67 |

| 65 | 2 1/2 | 76.1 | 190 | 177.8 | 149.2 | 22 | 19.1 | 8 | 28.6 | &/8211; | 77.6 | 74.7 | 19 | 100 | 41 | 5.35 |

| 80 | 3 | 88.9 | 210 | 190.5 | 168.3 | 22 | 19.1 | 8 | 31.8 | &/8211; | 90.5 | 90.7 | 21 | 117 | 46 | 7.06 |

///KLASSE 900///

| Nominale Größe | Außendurchmesser des Stahlrohrs A | Flansch-Außendurchmesser D | Größe der Verbindung | Flanschdicke C | Flansch-Innendurchmesser B1 | Steckdose | Flanschenhals großes Ende N | Flanschhöhe H | Theoretisches Gewicht Kg | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | Lochkreisdurchmesser der Schraube K | Mutiger Lochdurchmesser L | Bolzenloch Anzahl n(Stück) | B2 | U | ||||||||||

| 15 | ½ | 21.3 | 120 | 120.6 | 82.6 | 22 | 22.3 | 4 | 22.3 | &/8211; | 22.5 | 22.4 | 10 | 38 | 32 | 1.8 |

| 20 | ¾ | 26.9 | 130 | 130 | 88.9 | 22 | 22.3 | 4 | 25.4 | &/8211; | 27.5 | 27.7 | 11 | 44 | 35 | 2.41 |

| 25 | 1 | 33.7 | 150 | 149.3 | 101.6 | 26 | 25.4 | 4 | 28.6 | &/8211; | 34.5 | 34.5 | 13 | 52 | 41 | 3.55 |

| 32 | 1¼ | 42.4 | 160 | 158.7 | 111.1 | 26 | 25.4 | 4 | 28.6 | &/8211; | 43.5 | 43.2 | 14 | 64 | 41 | 4.02 |

| 40 | 1½ | 48.3 | 180 | 177.8 | 123.8 | 30 | 28.4 | 4 | 31.8 | &/8211; | 49.5 | 49.5 | 16 | 70 | 44 | 5.45 |

| 50 | 2 | 60.3 | 215 | 215.9 | 165.1 | 26 | 25.4 | 8 | 38.1 | &/8211; | 61.5 | 62 | 17 | 105 | 57 | 10.2 |

| 65 | 2½ | 76.1 | 245 | 244.3 | 190.5 | 30 | 28.4 | 8 | 41.3 | &/8211; | 77.6 | 74.7 | 19 | 124 | 64 | 13.9 |

Häufig gestellte Fragen (FAQs)

Was sind die idealen Anwendungen für Schweißmuffenflansche?

Schweißmuffenflansche eignen sich am besten für kleine Hochdruck-Rohrleitungssysteme, die aufgrund der möglichen Korrosion im Spaltbereich nicht mit hochkorrosiven Flüssigkeiten in Berührung kommen.

Wie sieht es mit der statischen Festigkeit und der Dauerfestigkeit von Schweißmuffenflanschen im Vergleich zu anderen Flanschen aus?

Muffenschweißflansche bieten eine ähnliche statische Festigkeit wie Aufsteckflansche, haben aber aufgrund der einzelnen Kehlnaht eine höhere Ermüdungsfestigkeit, was die Haltbarkeit bei schwankenden Belastungen verbessert.

Welche Werkstoffe gibt es für Schweißmuffenflansche?

Unsere Schweißmuffenflansche sind in einer Vielzahl von Werkstoffen erhältlich, darunter 304, 304L, 316L-Edelstähle und hochfeste Legierungen wie 2507 und 2205, die den unterschiedlichsten Anwendungsanforderungen gerecht werden.