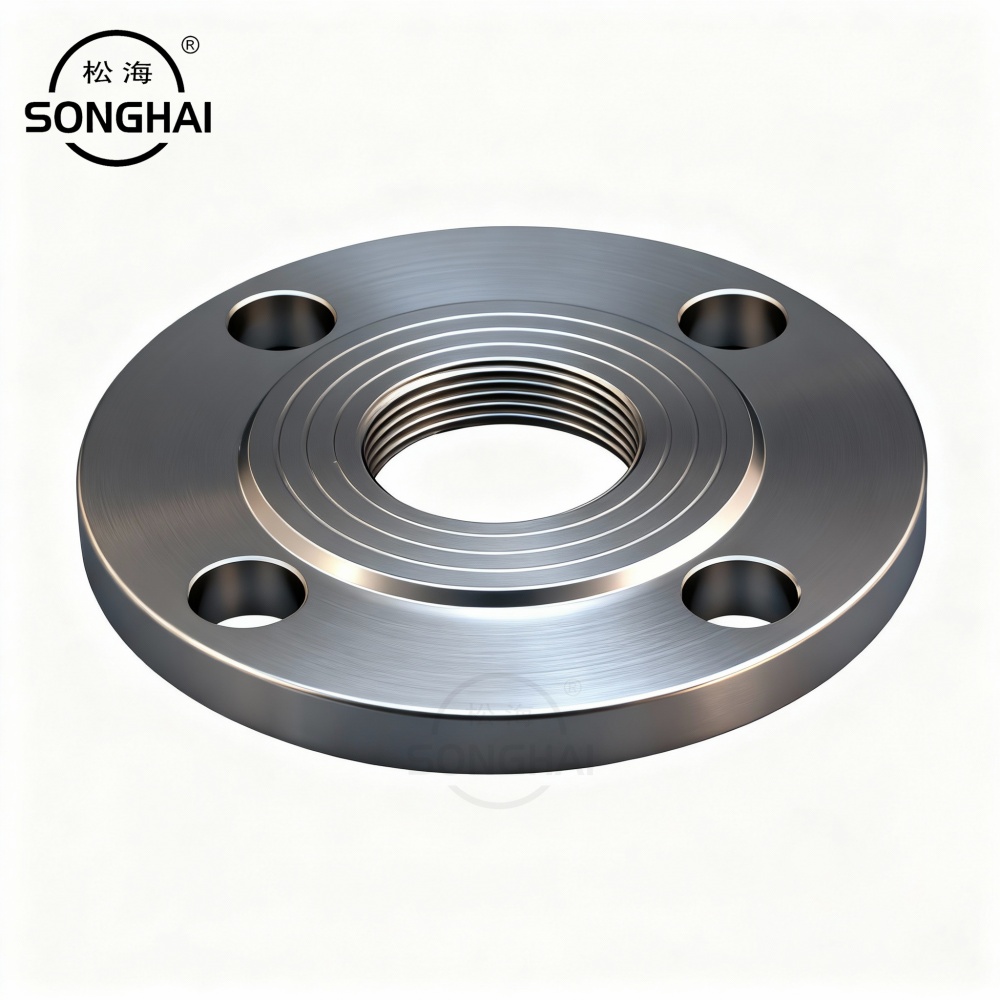

Flange cieche

Standard di certificazione

GB/T9119-2010

HG/T20592-2009

HG/T20615-2009

DIN

ASME

BS

JIS

Materiale: materiale

304:F304 S30408 S30408II S30408III S30400

304L:S30403 S30403II 30403 30403II

316L:31603 31603II 31603III

2507(F53)

2205(F51)

TP310S(06Cr5Ni20)

TP321(06Cr18Ni11)

S22053III=2205III

T321-32168=321

///Classe 150///

| Dimensione nominale | Dimensione del collegamento | spessore della flangia | |||||

|---|---|---|---|---|---|---|---|

| DN | NPS | Diametro esterno della flangia D | Diametro del cerchio centrale K | Diametro del foro del bullone L | Numero di fori per bulloni n | Bullone Th | C |

| 15 | 1/2 | 90 | 60.3 | 16 | 4 | M14 | 9.6 |

| 20 | 3/4 | 100 | 69.9 | 16 | 4 | M14 | 11.2 |

| 25 | 1 | 110 | 79.4 | 16 | 4 | M14 | 12.7 |

| 32 | 1 1/4 | 115 | 88.9 | 16 | 4 | M14 | 14.3 |

| 40 | 1 1/2 | 125 | 98.4 | 16 | 4 | M14 | 15.9 |

| 50 | 2 | 150 | 120.7 | 18 | 4 | M16 | 17.5 |

| 65 | 2 1/2 | 180 | 139.7 | 18 | 4 | M16 | 20.7 |

| 80 | 3 | 190 | 152.4 | 18 | 4 | M16 | 22.3 |

| 100 | 4 | 230 | 190.5 | 18 | 8 | M16 | 22.3 |

| 125 | 5 | 255 | 215.9 | 22 | 8 | M20 | 22.3 |

| 150 | 6 | 280 | 241.3 | 22 | 8 | M20 | 23.9 |

| 200 | 8 | 345 | 298.58 | 22 | 8 | M20 | 27.0 |

| 250 | 10 | 405 | 362.0 | 26 | 12 | M24 | 28.6 |

| 300 | 12 | 485 | 431.8 | 26 | 12 | M24 | 30.2 |

| 350 | 14 | 535 | 476.3 | 30 | 12 | M27 | 33.4 |

| 400 | 16 | 595 | 539.8 | 30 | 16 | M27 | 35.0 |

| 450 | 18 | 635 | 577.9 | 33 | 16 | M30 | 38.1 |

| 500 | 20 | 700 | 635.0 | 33 | 20 | M30 | 41.3 |

| 600 | 24 | 815 | 749.3 | 36 | 20 | M33 | 46.1 |

///CLASSE 300///

| Dimensione nominale | Dimensione del collegamento | spessore della flangia | |||||

|---|---|---|---|---|---|---|---|

| DN | NPS | Diametro esterno della flangia D | Diametro del cerchio centrale K | Diametro del foro del bullone L | Numero di fori per bulloni n | Bullone Th | C |

| 15 | 1/2 | 95 | 66.7 | 16 | 4 | M14 | 12.7 |

| 20 | 3/4 | 115 | 82.6 | 18 | 4 | M16 | 14.3 |

| 25 | 1 | 125 | 88.9 | 18 | 4 | M16 | 15.9 |

| 32 | 1 1/4 | 135 | 98.4 | 18 | 4 | M16 | 17.5 |

| 40 | 1 1/2 | 155 | 114.3 | 22 | 4 | M20 | 19.1 |

| 50 | 2 | 165 | 127.0 | 18 | 8 | M16 | 20.7 |

| 65 | 2 1/2 | 190 | 149.2 | 22 | 8 | M20 | 23.9 |

| 80 | 3 | 210 | 168.3 | 22 | 8 | M20 | 27.0 |

| 100 | 4 | 255 | 200.0 | 22 | 8 | M20 | 30.2 |

| 125 | 5 | 280 | 235.0 | 22 | 8 | M20 | 33.4 |

| 150 | 6 | 320 | 269.9 | 22 | 12 | M20 | 35.0 |

| 200 | 8 | 380 | 330.2 | 26 | 12 | M24 | 39.7 |

| 250 | 10 | 445 | 387.4 | 30 | 16 | M27 | 46.1 |

| 300 | 12 | 520 | 450.8 | 33 | 16 | M30 | 49.3 |

| 350 | 14 | 585 | 514.4 | 33 | 20 | M30 | 52.4 |

| 400 | 16 | 650 | 571.5 | 36 | 20 | M33 | 55.6 |

| 450 | 18 | 710 | 628.6 | 36 | 24 | M33 | 58.8 |

| 500 | 20 | 775 | 685.8 | 36 | 24 | M33 | 62.0 |

| 600 | 24 | 915 | 812.8 | 42 | 24 | M39X3 | 68.3 |

///CLASSE 600///

| Dimensione nominale | Dimensione del collegamento | spessore della flangia | |||||

|---|---|---|---|---|---|---|---|

| DN | NPS | Diametro esterno della flangia D | Diametro del cerchio centrale K | Diametro del foro del bullone L | Numero di fori per bulloni n | Bullone Th | C |

| 15 | 1/2 | 95 | 66.7 | 16 | 4 | M14 | 14.3 |

| 20 | 3/4 | 115 | 82.6 | 18 | 4 | M16 | 15.9 |

| 25 | 1 | 125 | 88.9 | 18 | 4 | M16 | 17.5 |

| 32 | 1 1/4 | 135 | 98.4 | 18 | 4 | M16 | 20.7 |

| 40 | 1 1/2 | 155 | 114.3 | 22 | 4 | M20 | 22.3 |

| 50 | 2 | 165 | 127.0 | 18 | 8 | M16 | 25.4 |

| 65 | 2 1/2 | 190 | 149.2 | 22 | 8 | M20 | 28.6 |

| 80 | 3 | 210 | 168.3 | 22 | 8 | M20 | 31.8 |

| 100 | 4 | 275 | 215.9 | 26 | 8 | M24 | 38.1 |

| 125 | 5 | 330 | 266.7 | 30 | 8 | M27 | 44.5 |

| 150 | 6 | 355 | 292.1 | 30 | 12 | M27 | 47.7 |

| 200 | 8 | 420 | 349.2 | 33 | 12 | M30 | 55.6 |

| 250 | 10 | 510 | 431.8 | 36 | 16 | M33 | 63.5 |

| 300 | 12 | 560 | 489.0 | 36 | 20 | M33 | 66.7 |

| 350 | 14 | 605 | 527.0 | 39 | 20 | M36X3 | 69.9 |

| 400 | 16 | 685 | 603.2 | 42 | 20 | M39X3 | 76.2 |

| 450 | 18 | 745 | 654.0 | 45 | 20 | M42X3 | 82.6 |

| 500 | 20 | 815 | 723.9 | 45 | 24 | M42X3 | 88.9 |

| 600 | 24 | 940 | 838.2 | 51 | 24 | M48X3 | 101.6 |

///CLASSE 900//

| Dimensione nominale | Dimensione del collegamento | spessore della flangia | |||||

|---|---|---|---|---|---|---|---|

| DN | NPS | Diametro esterno della flangia D | Diametro del cerchio centrale K | Diametro del foro del bullone L | Numero di fori per bulloni n | Bullone Th | C |

| 15 | 1/2 | 120 | 82.6 | 22 | 4 | M20 | 22.3 |

| 20 | 3/4 | 130 | 88.9 | 22 | 4 | M20 | 25.4 |

| 25 | 1 | 150 | 101.6 | 26 | 4 | M24 | 28.6 |

| 32 | 1 1/4 | 160 | 111.1 | 26 | 4 | M24 | 28.6 |

| 40 | 1 1/2 | 180 | 123.8 | 30 | 4 | M27 | 31.8 |

| 50 | 2 | 215 | 165.1 | 26 | 8 | M24 | 38.1 |

| 65 | 2 1/2 | 245 | 190.5 | 30 | 8 | M27 | 41.3 |

| 80 | 3 | 240 | 190.5 | 26 | 8 | M24 | 38.1 |

| 100 | 4 | 290 | 235.0 | 33 | 8 | M30 | 44.5 |

| 125 | 5 | 350 | 279.4 | 36 | 8 | M33 | 50.8 |

| 150 | 6 | 380 | 317.5 | 33 | 12 | M30 | 55.6 |

| 200 | 8 | 470 | 393.7 | 39 | 12 | M36X3 | 63.5 |

| 250 | 10 | 545 | 469.9 | 39 | 16 | M36X3 | 69.9 |

| 300 | 12 | 610 | 533.4 | 39 | 20 | M36X3 | 79.4 |

| 350 | 14 | 640 | 558.8 | 42 | 20 | M39X3 | 85.8 |

| 400 | 16 | 705 | 616.0 | 45 | 20 | M42X3 | 88.9 |

| 450 | 18 | 785 | 685.8 | 51 | 20 | M48X3 | 101.6 |

| 500 | 20 | 855 | 749.3 | 55 | 20 | M52X3 | 108.0 |

| 600 | 24 | 1040 | 901.7 | 68 | 20 | M64X3 | 139.7 |

///CLASSE 1500///

| Dimensione nominale | Dimensione del collegamento | spessore della flangia | |||||

|---|---|---|---|---|---|---|---|

| DN | NPS | Diametro esterno della flangia D | Diametro del cerchio centrale K | Diametro del foro del bullone L | Numero di fori per bulloni n | Bullone Th | C |

| 15 | 1/2 | 120 | 82.6 | 22 | 4 | M20 | 22.3 |

| 20 | 3/4 | 130 | 88.9 | 22 | 4 | M20 | 25.4 |

| 25 | 1 | 150 | 101.6 | 26 | 4 | M24 | 28.6 |

| 32 | 1 1/4 | 160 | 111.1 | 26 | 4 | M24 | 28.6 |

| 40 | 1 1/2 | 180 | 123.8 | 30 | 4 | M27 | 31.8 |

| 50 | 2 | 215 | 165.1 | 26 | 8 | M24 | 38.1 |

| 65 | 2 1/2 | 245 | 190.5 | 30 | 8 | M27 | 41.3 |

| 80 | 3 | 265 | 203.2 | 33 | 8 | M30 | 47.7 |

| 100 | 4 | 310 | 241.3 | 36 | 8 | M33 | 54.0 |

| 125 | 5 | 375 | 292.1 | 42 | 8 | M39X3 | 73.1 |

| 150 | 6 | 395 | 317.5 | 39 | 12 | M36X3 | 82.6 |

| 200 | 8 | 485 | 393.7 | 45 | 12 | M42X3 | 92.1 |

| 250 | 10 | 585 | 482.6 | 51 | 12 | M48X3 | 108.0 |

| 300 | 12 | 675 | 571.5 | 55 | 16 | M52X3 | 123.9 |

| 350 | 14 | 750 | 635.0 | 60 | 16 | M56X3 | 133.4 |

| 400 | 16 | 825 | 704.8 | 68 | 16 | M64X3 | 146.1 |

| 450 | 18 | 915 | 774.7 | 74 | 16 | M70X3 | 162.0 |

| 500 | 20 | 985 | 831.8 | 80 | 16 | M76X3 | 177.8 |

| 600 | 24 | 1170 | 990.6 | 94 | 16 | M90X3 | 203.2 |

///CLASSE 2500//

| Dimensione nominale | Dimensione del collegamento | spessore della flangia | |||||

|---|---|---|---|---|---|---|---|

| DN | NPS | Diametro esterno della flangia D | Diametro del cerchio centrale K | Diametro del foro del bullone L | Numero di fori per bulloni n | Bullone Th | C |

| 15 | 1/2 | 135 | 88.9 | 22 | 4 | M20 | 30.2 |

| 20 | 3/4 | 140 | 95.2 | 22 | 4 | M20 | 31.8 |

| 25 | 1 | 160 | 108.0 | 26 | 4 | M24 | 35.0 |

| 32 | 1 1/4 | 185 | 130.2 | 30 | 4 | M27 | 38.1 |

| 40 | 1 1/2 | 205 | 146.0 | 33 | 4 | M30 | 44.5 |

| 50 | 2 | 235 | 171.4 | 30 | 8 | M27 | 50.9 |

| 65 | 2 1/2 | 265 | 196.8 | 33 | 8 | M30 | 57.2 |

| 80 | 3 | 305 | 228.6 | 36 | 8 | M33 | 66.7 |

| 100 | 4 | 355 | 273.0 | 42 | 8 | M39X3 | 76.2 |

| 125 | 5 | 420 | 323.8 | 48 | 8 | M45X3 | 92.1 |

| 150 | 6 | 485 | 368.3 | 55 | 8 | M52X3 | 108.0 |

| 200 | 8 | 550 | 438.2 | 55 | 12 | M52X3 | 127.0 |

| 250 | 10 | 675 | 539.8 | 68 | 12 | M64X3 | 165.1 |

| 300 | 12 | 760 | 619.1 | 74 | 12 | M70X3 | 184.2 |

Domande frequenti (FAQ)

Qual è lo scopo di una flangia cieca?

Una flangia cieca viene utilizzata per sigillare l'estremità di una tubazione, di una valvola o di un recipiente in pressione, bloccando efficacemente il flusso del fluido e prevenendo le perdite.

Le flange cieche possono essere utilizzate per la manutenzione?

Sì, le flange cieche possono essere facilmente svitate per consentire l'accesso per la manutenzione, l'ispezione o la pulizia all'interno dell'estremità terminale del tubo o del recipiente in pressione.

Perché le flange cieche sono vendute a un costo superiore rispetto alle altre flange?

Sebbene siano più facili da produrre, le flange cieche sono vendute con un prezzo maggiorato a causa della loro elevata resistenza meccanica e dei requisiti specifici per le forze di avvitamento e la resistenza alla pressione.