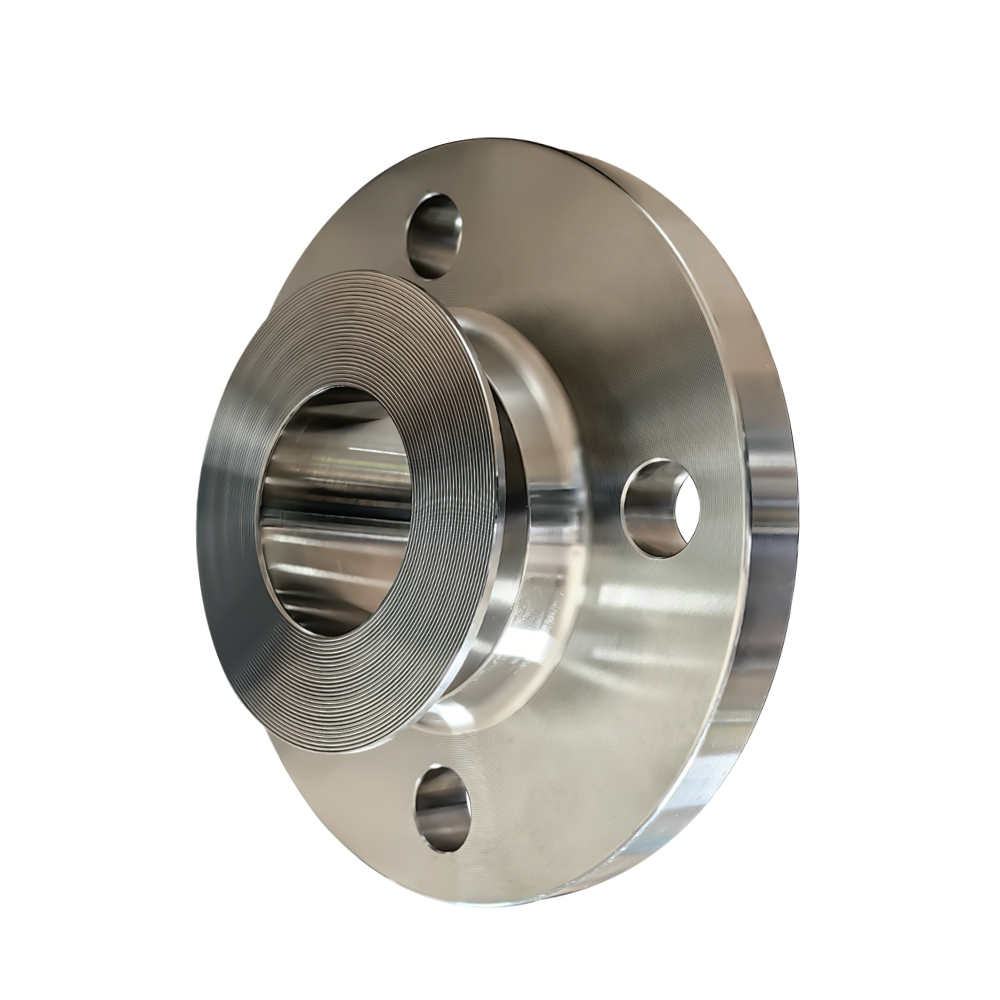

Lap Joint Flanges

Certification standards

They solve issues related to welding complexities and material compatibility by allowing the backing flange to be made from a more affordable material like carbon steel, while the stub end matches the pipe’s grade.

This design not only facilitates easier assembly and disassembly but also reduces costs without compromising functionality. Ideal for systems where space is constrained and frequent access is necessary,

GB/T9119-2010

HG/T20592-2009

HG/T20615-2009

DIN

ASME

BS

JIS

Material:

304:F304 S30408 S30408II S30408III S30400

304L:S30403 S30403II 30403 30403II

316L:31603 31603II 31603III

2507(F53)

2205(F51)

TP310S(06Cr5Ni20)

TP321(06Cr18Ni11)

S22053III=2205III

T321-32168=321

Lap joint flanges feature a flat face and are always used in conjunction with a stub end.

A lap joint flange slips over the pipe and seats on the back of the stub end and the two are kept together by the pressure of the bolts.

///CLASS 150///

| Nominal size | Steel Pipe outer diameter | Flange outer diameter | Connection size | flange thickness | Flange inner diameter | Flange neck big end | Flange height | Rounded comers | Butt welding ring | Theotical weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | D | Bolt hole center circle diameter K | Bolt hole diameter L | Bolt hole quantity n(pieces) | C | B | N | H | R1 | high H | outer diameter d | Kg | ||

| 15 | 1/2 | 21.3 | 90 | 88.9 | 60.3 | 16 | 15.7 | 4 | 11.2 | 22.9 | 30 | 16 | 3 | 51 | 34.9 | 0.38 |

| 20 | 3/4 | 26.9 | 100 | 98.6 | 69.9 | 16 | 15.7 | 4 | 12.7 | 28.2 | 38 | 16 | 3 | 51 | 42.9 | 0.55 |

| 25 | 1 | 33.7 | 110 | 108 | 79.4 | 16 | 15.7 | 4 | 14.3 | 34.9 | 49 | 17 | 3 | 51 | 50.8 | 0.76 |

| 32 | 1 1/4 | 42.4 | 115 | 117.3 | 88.9 | 16 | 15.7 | 4 | 15.9 | 43.7 | 59 | 21 | 5 | 51 | 63.5 | 1.01 |

| 40 | 1 1/2 | 48.3 | 125 | 127 | 98.4 | 16 | 15.7 | 4 | 17.5 | 50.0 | 65 | 22 | 6 | 51 | 73.0 | 1.3 |

| 50 | 2 | 60.3 | 150 | 152.4 | 120.7 | 18 | 19.1 | 4 | 19.1 | 62.5 | 78 | 25 | 8 | 64 | 92.1 | 2.03 |

| 65 | 2 1/2 | 76.1 | 180 | 177.8 | 139.7 | 18 | 19.1 | 4 | 22.3 | 78.5/75.4 | 90 | 29 | 8 | 64 | 104.8 | 3.25 |

| 80 | 3 | 88.9 | 190 | 190.5 | 152.4 | 18 | 19.1 | 4 | 23.9 | 91.4 | 108 | 30 | 10 | 64 | 127.0 | 3.81 |

| 100 | 4 | 114.3 | 230 | 228.6 | 190.5 | 18 | 19.1 | 8 | 23.9 | 116.8 | 135 | 33 | 11 | 76 | 157.2 | 5.25 |

| 125 | 5 | 139.7 | 255 | 254 | 215.9 | 22 | 22.4 | 8 | 23.9 | 144.4 | 164 | 36 | 11 | 76 | 185.7 | 6.02 |

| 150 | 6 | 168.3 | 280 | 278.4 | 241.3 | 22 | 22.4 | 8 | 25.4 | 171.4 | 192 | 40 | 13 | 89 | 215.9 | 7.4 |

| 200 | 8 | 219.1 | 345 | 342.9 | 298.58 | 22 | 22.4 | 8 | 28.6 | 222.2 | 246 | 44 | 13 | 102 | 269.9 | 12.1 |

| 250 | 10 | 273 | 405 | 406.4 | 362.0 | 26 | 25.4 | 12 | 30.2 | 277.4 | 305 | 49 | 13 | 127 | 323.8 | 16.4 |

| 300 | 12 | 323.9 | 485 | 482.6 | 431.8 | 26 | 25.4 | 12 | 31.8 | 328.2 | 365 | 56 | 13 | 152 | 381.0 | 26.1 |

| 350 | 14 | 355.6 | 535 | 533.4 | 476.2 | 30 | 28.4 | 12 | 35.0 | 360.2 | 400 | 79 | 13 | 152 | 412.8 | 34.5 |

| 400 | 16 | 406.4 | 595 | 596.9 | 539.8 | 30 | 28.4 | 16 | 36.6 | 411.2 | 457 | 87 | 13 | 152 | 469.9 | 44.6 |

| 450 | 18 | 457 | 635 | 635 | 577.9 | 33 | 31.75 | 16 | 39.7 | 462.3 | 505 | 97 | 13 | 152 | 533.4 | 48.7 |

| 500 | 20 | 508 | 700 | 698.5 | 635.0 | 33 | 31.75 | 20 | 42.9 | 514.4 | 559 | 103 | 13 | 152 | 584.2 | 61.6 |

| 600 | 24 | 610 | 815 | 812.8 | 749.3 | 36 | 35.1 | 20 | 47.7 | 616.0 | 663 | 111 | 13 | 152 | 692.2 | 86.6 |

///CLASS 300///

| Nominal size | Steel Pipe outer diameter | Flange outer diameter | Connection size | flange thickness | Flange inner diameter | Flange neck big end | Flange height | Rounded corners | Butt welding ring | Theotical weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | D | Bolt hole center circle diameter K | Bolt hole diameter L | Bolt hole quantity n(pieces) | C | B | N | H | R1 | high H | outer diameter d | Kg | ||

| 15 | 1/2 | 21.3 | 95 | 88.9 | 66.7 | 16 | 15.7 | 4 | 14.3 | 22.9 | 38 | 22 | 3 | 51 | 34.9 | 0.62 |

| 20 | 3/4 | 26.9 | 115 | 98.6 | 82.6 | 18 | 15.7 | 4 | 15.9 | 28.2 | 48 | 25 | 3 | 51 | 42.9 | 1.1 |

| 25 | 1 | 33.7 | 125 | 108 | 88.9 | 18 | 15.7 | 4 | 17.5 | 34.9 | 54 | 27 | 3 | 51 | 50.8 | 1.33 |

| 32 | 1 1/4 | 42.4 | 135 | 117.3 | 98.4 | 18 | 15.7 | 4 | 19.1 | 43.7 | 64 | 27 | 5 | 51 | 63.5 | 1.65 |

| 40 | 1 1/2 | 48.3 | 155 | 127 | 114.3 | 22 | 15.7 | 4 | 20.7 | 50.0 | 70 | 30 | 6 | 51 | 73.0 | 2.44 |

| 50 | 2 | 60.3 | 165 | 152.4 | 127.0 | 18 | 19.1 | 8 | 22.3 | 62.5 | 84 | 33 | 8 | 64 | 92.1 | 2.83 |

| 65 | 2 1/2 | 76.1 | 190 | 177.8 | 149.2 | 22 | 19.1 | 8 | 25.4 | 78.5/75.4 | 100 | 38 | 8 | 64 | 104.8 | 4.25 |

| 80 | 3 | 88.9 | 210 | 190.5 | 168.3 | 22 | 19.1 | 8 | 28.6 | 91.4 | 117 | 43 | 10 | 64 | 127.0 | 5.78 |

| 100 | 4 | 114.3 | 255 | 228.6 | 200.0 | 22 | 19.1 | 8 | 31.8 | 116.8 | 146 | 48 | 11 | 76 | 157.2 | 9.55 |

| 125 | 5 | 139.7 | 280 | 254 | 235.0 | 22 | 22.4 | 8 | 35.0 | 144.4 | 178 | 51 | 11 | 76 | 185.7 | 12.2 |

| 150 | 6 | 168.3 | 320 | 279.4 | 269.9 | 22 | 22.4 | 12 | 36.6 | 171.4 | 206 | 52 | 13 | 89 | 215.9 | 15.5 |

| 200 | 8 | 219.1 | 380 | 342.9 | 330.2 | 26 | 22.4 | 12 | 41.3 | 222.2 | 260 | 62 | 13 | 102 | 269.9 | 24.1 |

| 250 | 10 | 273 | 445 | 406.4 | 387.4 | 30 | 25.4 | 16 | 47.7 | 277.1 | 321 | 95 | 13 | 254 | 323.8 | 34.4 |

| 300 | 12 | 323.9 | 520 | 482.6 | 450.8 | 33 | 25.4 | 16 | 50.8 | 328.2 | 375 | 102 | 13 | 254 | 381.0 | 50.4 |

| 350 | 14 | 355.6 | 585 | 533.4 | 514.4 | 33 | 28.4 | 20 | 54.0 | 360.2 | 425 | 111 | 13 | 305 | 412.8 | 70.9 |

| 400 | 16 | 406.4 | 650 | 596.9 | 571.5 | 36 | 28.4 | 20 | 57.2 | 411.2 | 483 | 121 | 13 | 305 | 469.9 | 89.5 |

| 450 | 18 | 457 | 710 | 635 | 628.6 | 36 | 31.75 | 24 | 60.4 | 462.3 | 533 | 130 | 13 | 305 | 533.4 | 111 |

| 500 | 20 | 508 | 775 | 698.5 | 685.8 | 36 | 31.75 | 24 | 63.5 | 514.4 | 587 | 140 | 13 | 305 | 584.2 | 137 |

| 600 | 24 | 610 | 915 | 812.8 | 812.8 | 42 | 35.1 | 24 | 69.9 | 616.0 | 702 | 152 | 13 | 305 | 692.2 | 204 |

///CLASS 600///

| Nominal size | Steel Pipe outer diameter | Flange outer diameter | Connection size | flange thickness | Flange inner diameter | Flange neck big end | Flange height | Rounded corners | Butt welding ring | Theotical weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | D | Bolt hole center circle diameter K | Bolt hole diameter L | Bolt hole quantity n(pieces) | C | B | N | H | R1 | high H | outer diameter d | Kg | ||

| 15 | 1/2 | 21.3 | 95 | 88.9 | 66.7 | 16 | 15.7 | 4 | 14.3 | 22.9 | 38 | 22 | 3 | 76 | 34.9 | 0.72 |

| 20 | 3/4 | 26.9 | 115 | 98.6 | 82.6 | 18 | 15.7 | 4 | 15.9 | 28.2 | 48 | 25 | 3 | 76 | 42.9 | 1.25 |

| 25 | 1 | 33.7 | 125 | 108 | 88.9 | 18 | 15.7 | 4 | 17.5 | 34.9 | 54 | 27 | 3 | 102 | 50.8 | 1.5 |

| 32 | 11/4 | 42.4 | 135 | 117.3 | 98.4 | 18 | 15.7 | 4 | 20.7 | 43.7 | 64 | 29 | 5 | 102 | 63.5 | 2 |

| 40 | 11/2 | 48.3 | 155 | 127 | 114.3 | 22 | 15.7 | 4 | 22.3 | 50.0 | 70 | 32 | 6 | 102 | 73.0 | 2.92 |

| 50 | 2 | 60.3 | 165 | 152.4 | 127.0 | 18 | 19.1 | 8 | 25.4 | 62.5 | 84 | 37 | 8 | 152 | 92.1 | 3.55 |

| 65 | 21/2 | 76.1 | 190 | 177.8 | 149.2 | 22 | 19.1 | 8 | 28.6 | 78.5/75.4 | 100 | 41 | 8 | 152 | 104.8 | 5.23 |

| 80 | 3 | 88.9 | 210 | 190.5 | 168.3 | 22 | 19.1 | 8 | 31.8 | 91.4 | 117 | 46 | 10 | 152 | 127.0 | 6.95 |

| 100 | 4 | 114.3 | 275 | 228.6 | 215.9 | 26 | 19.1 | 8 | 38.1 | 116.8 | 152 | 54 | 11 | 152 | 157.2 | 14.4 |

| 125 | 5 | 139.7 | 330 | 254 | 266.7 | 30 | 22.4 | 8 | 44.5 | 144.4 | 189 | 60 | 11 | 203 | 185.7 | 24.3 |

| 150 | 6 | 168.3 | 355 | 279.4 | 292.1 | 30 | 22.4 | 12 | 47.7 | 171.4 | 222 | 67 | 13 | 203 | 215.9 | 28.5 |

| 200 | 8 | 219.1 | 420 | 342.9 | 349.2 | 33 | 22.4 | 12 | 55.6 | 222.2 | 273 | 76 | 13 | 203 | 269.9 | 43.1 |

| 250 | 10 | 273 | 510 | 406.4 | 431.8 | 36 | 25.4 | 16 | 63.5 | 277.4 | 343 | 111 | 13 | 254 | 323.8 | 70.5 |

| 300 | 12 | 323.9 | 560 | 482.6 | 489.0 | 36 | 25.4 | 20 | 66.7 | 328.2 | 400 | 117 | 13 | 254 | 381.0 | 86.1 |

| 350 | 14 | 355.6 | 605 | 533.4 | 527.0 | 39 | 28.4 | 20 | 69.9 | 360.2 | 432 | 127 | 13 | 305 | 412.8 | 100 |

| 400 | 16 | 406.4 | 685 | 596.9 | 603.2 | 42 | 28.4 | 20 | 76.2 | 411.2 | 495 | 140 | 13 | 305 | 469.9 | 145 |

| 450 | 18 | 457 | 745 | 635 | 654.0 | 45 | 31.75 | 20 | 82.6 | 462.3 | 546 | 152 | 13 | 305 | 533.4 | 177 |

| 500 | 20 | 508 | 815 | 698.5 | 723.9 | 45 | 31.75 | 24 | 88.9 | 514.4 | 610 | 165 | 13 | 305 | 584.2 | 225 |

| 600 | 24 | 610 | 940 | 812.8 | 838.2 | 51 | 35.1 | 24 | 101.6 | 616.0 | 718 | 184 | 13 | 305 | 692.2 | 318 |

Frequently Asked Questions (FAQs)

What are lap joint flanges used for?

Applications where ease of alignment and assembly is crucial, such as in piping systems with frequent disassembly or inspection.

What are the benefits of using lap joint flanges?

Ease of installation and alignment, ability to accommodate pipe misalignment, and the flexibility of using a backing flange to match different pipe sizes or configurations.

How do lap joint flanges differ from other flange types?

Consist of two parts: a loose backing flange and a lap joint flange, allowing for easier alignment and adjustments without welding.