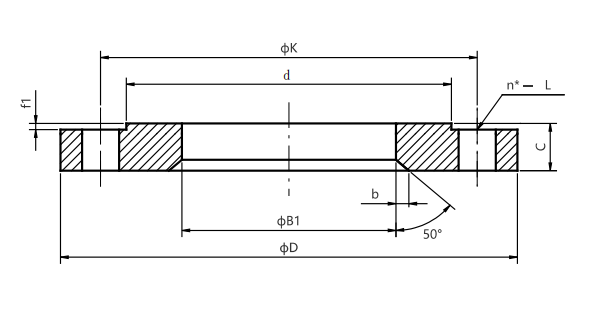

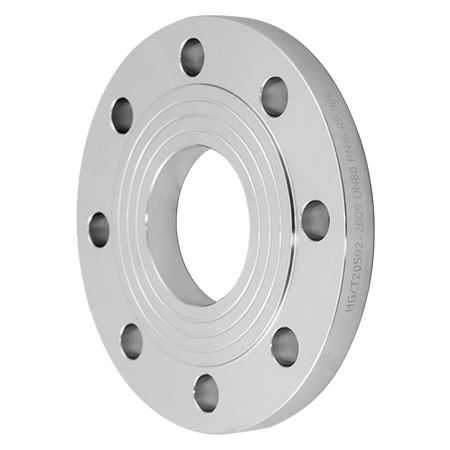

Plate flanges

Certification standards

GB/T9119-2010、HG/T20592-2009、HG/T20615-2009、DIN、ASME、BS、JIS

304:F304 S30408 S30408II S30408III S30400

304L:S30403 S30403II 30403 30403II

316L:31603 31603II 31603III

2507(F53)

2205(F51)

TP310S(06Cr5Ni20)

TP321(06Cr18Ni11)

S22053III=2205III

T321-32168=321

Plate flange is the most common flange, the pressure is PN2.5, PN6, PN10, PN16, PN25.

Welding form: flat welding flange is to insert the pipe into the flange to weld.please see the download section on the right.

- Versatility: suitable for industries and applications (Chemical, Construction, Water Supply, Shipbuilding)

- Compliance: adheres to multiple international standards (GB/T9119-2010, HG/T20592-2009, HG/T20615-2009, DIN, ASME, BS, and JIS)

- Durability: made from premium materials that resist corrosion and wear (304, 304L, 316L, 2507, 2205, TP310S, TP321)

- Affordability: competitive, discounted price for bulk order

- Pressure-Rated: Available in PN2.5, PN6, PN10, PN16, PN25

Frequently Asked Questions (FAQs)

What is a plate flange used for?

Plate flanges are commonly used to connect pipes, valves, and other equipment in low-pressure applications. They provide a flat, strong connection that can be easily assembled and disassembled, making them ideal for industries like water treatment, oil and gas, and HVAC systems.

What materials are your plate flanges made from?

Our plate flanges are typically made from (Duplex) stainless steel including 304, 304L, 316L, 2507, 2205, TP310S, TP321

How are plate flanges installed?

Plate flanges are installed by welding them to the end of a pipe, then bolting them to another flange or piece of equipment. The flat surface of the flange ensures a tight seal, and gaskets are often used to enhance the seal between flanges.