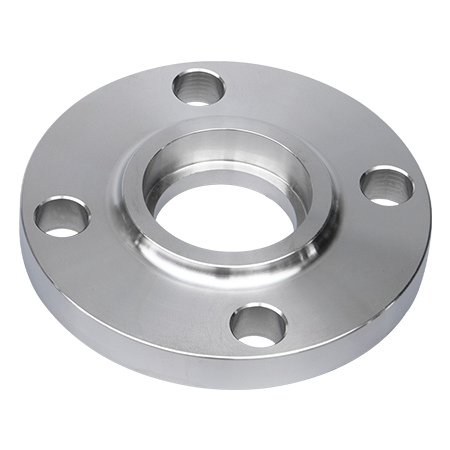

Фланец под раструбную сварку

Стандарты сертификации

Designed for superior sealing and strength, these flanges are ideal for use in demanding industries such as petroleum, chemical processing, natural gas, and power stations.

GB/T9119-2010

HG/T20592-2009

HG/T20615-2009

DIN

ASME

BS

JIS

Материал:

304:F304 S30408 S30408II S30408III S30400

304L:S30403 S30403II 30403 30403II

316L:31603 31603II 31603III

2507(F53)

2205(F51)

TP310S(06Cr5Ni20)

TP321(06Cr18Ni11)

S22053III=2205III

T321-32168=321

Socket Weld Flanges are used for small-size and high-pressure piping that do not transfer highly corrosive fluids.This due to the fact that these flange types are subject to corrosion in the gap area between the end of the pipe and the shoulder of the socket.

/// КЛАСС 150///

| Номинальный размер | Steel pipe outer diameter A | Наружный диаметр фланца D | Размер соединения | flange thickness C | Flange inner diameter B1 | Socket | Flange neck big end N | Flange height H | Theoretical weight Kg | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | Bolt hole center circle diameter K | Bold hole diameter L | Bolt hole Quantity n(pieces) | B2 | U | |||||||||||

| 15 | 1/2 | 21.3 | 90 | 88.9 | 60.3 | 16 | 15.7 | 4 | 9.6 | 15.5 | 15.7 | 22.5 | 22.4 | 10 | 30 | 14 | 0.42 |

| 20 | 3/4 | 26.9 | 100 | 98.6 | 69.9 | 16 | 15.7 | 4 | 11.2 | 21 | 20.8 | 27.5 | 27.7 | 11 | 38 | 14 | 0.59 |

| 25 | 1 | 33.7 | 110 | 108 | 79.4 | 16 | 15.7 | 4 | 12.7 | 27 | 26.7 | 34.5 | 34.5 | 13 | 49 | 16 | 0.81 |

| 32 | 1 1/4 | 42.4 | 115 | 117.3 | 88.9 | 16 | 15.7 | 4 | 14.3 | 35 | 35.1 | 43.5 | 43.2 | 14 | 59 | 19 | 1.07 |

| 40 | 1 1/2 | 48.3 | 125 | 127 | 98.4 | 16 | 15.7 | 4 | 15.9 | 41 | 40.9 | 49.5 | 49.5 | 16 | 65 | 21 | 1.36 |

| 50 | 2 | 60.3 | 150 | 152.4 | 120.7 | 18 | 19.1 | 4 | 17.5 | 52 | 52.6 | 61.5 | 62 | 17 | 78 | 24 | 2.1 |

| 65 | 2 1/2 | 76.1 | 180 | 177.8 | 139.7 | 18 | 19.1 | 4 | 20.7 | 66 | 62.7 | 77.6 | 74.7 | 19 | 90 | 27 | 3.33 |

| 80 | 3 | 88.9 | 190 | 190.5 | 152.4 | 18 | 19.1 | 4 | 22.3 | 77.5 | 78 | 90.5 | 90.7 | 21 | 108 | 29 | 3.9 |

///КЛАСС 300///

| Номинальный размер | Steel pipe outer diameter A | Наружный диаметр фланца D | Размер соединения | flange thickness C | Flange inner diameter B1 | Socket | Flange neck big end N | Flange height H | Theoretical weight Kg | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | Bolt hole center circle diameter K | Bold hole diameter L | Bolt hole Quantity n(pieces) | B2 | U | |||||||||||

| 15 | ½ | 21.3 | 95 | 88.9 | 66.7 | 16 | 15.7 | 4 | 12.7 | 15.5 | 15.7 | 22.5 | 22.4 | 10 | 38 | 21 | 0.66 |

| 20 | ¾ | 26.9 | 115 | 98.6 | 82.6 | 18 | 15.7 | 4 | 14.3 | 21 | 20.8 | 27.5 | 27.7 | 11 | 48 | 24 | 1.15 |

| 25 | 1 | 33.7 | 125 | 108 | 88.9 | 18 | 15.7 | 4 | 15.9 | 27 | 26.7 | 34.5 | 34.5 | 13 | 54 | 25 | 1.4 |

| 32 | 1 ¼ | 42.4 | 135 | 117.3 | 98.4 | 18 | 15.7 | 4 | 17.5 | 35 | 35.1 | 43.5 | 43.2 | 14 | 64 | 25 | 1.75 |

| 40 | 1 ½ | 48.3 | 155 | 127 | 114.3 | 22 | 15.7 | 4 | 19.1 | 41 | 40.9 | 49.5 | 49.5 | 16 | 70 | 29 | 2.55 |

| 50 | 2 | 60.3 | 165 | 152.4 | 127 | 18 | 19.1 | 8 | 20.7 | 52 | 52.6 | 61.5 | 62 | 17 | 84 | 32 | 2.93 |

| 65 | 2 ½ | 76.1 | 190 | 177.8 | 149.2 | 22 | 19.1 | 8 | 23.9 | 66 | 62.7 | 77.6 | 74.7 | 19 | 100 | 37 | 4.4 |

| 80 | 3 | 88.9 | 210 | 190.5 | 168.3 | 22 | 19.1 | 8 | 27 | 77.5 | 78 | 90.5 | 90.7 | 21 | 117 | 41 | 5.92 |

///КЛАСС 600///

| Номинальный размер | Steel pipe outer diameter A | Наружный диаметр фланца D | Размер соединения | flange thickness C | Flange inner diameter B1 | Socket | Flange neck big end N | Flange height H | Theoretical weight Kg | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | Bolt hole center circle diameter K | Bold hole diameter L | Bolt hole Quantity n(pieces) | B2 | U | ||||||||||

| 15 | 1/2 | 21.3 | 95 | 88.9 | 66.7 | 16 | 15.7 | 4 | 14.3 | &/8211; | 22.5 | 22.4 | 10 | 38 | 22 | 0.76 |

| 20 | 3/4 | 26.9 | 115 | 98.6 | 82.6 | 18 | 15.7 | 4 | 15.9 | &/8211; | 27.5 | 27.7 | 11 | 48 | 25 | 1.29 |

| 25 | 1 | 33.7 | 125 | 108 | 88.9 | 18 | 15.7 | 4 | 17.5 | &/8211; | 34.5 | 34.5 | 13 | 54 | 27 | 1.55 |

| 32 | 1 1/4 | 424 | 135 | 117.3 | 98.4 | 18 | 15.7 | 4 | 20.7 | &/8211; | 43.5 | 43.2 | 14 | 64 | 29 | 2.06 |

| 40 | 1 1/2 | 48.3 | 155 | 127 | 114.3 | 22 | 15.7 | 4 | 22.3 | &/8211; | 49.5 | 49.5 | 16 | 70 | 32 | 3.00 |

| 50 | 2 | 60.3 | 165 | 152.4 | 127 | 18 | 19.1 | 8 | 25.4 | &/8211; | 61.5 | 62 | 17 | 84 | 37 | 3.67 |

| 65 | 2 1/2 | 76.1 | 190 | 177.8 | 149.2 | 22 | 19.1 | 8 | 28.6 | &/8211; | 77.6 | 74.7 | 19 | 100 | 41 | 5.35 |

| 80 | 3 | 88.9 | 210 | 190.5 | 168.3 | 22 | 19.1 | 8 | 31.8 | &/8211; | 90.5 | 90.7 | 21 | 117 | 46 | 7.06 |

///КЛАСС 900///

| Номинальный размер | Steel pipe outer diameter A | Наружный диаметр фланца D | Размер соединения | flange thickness C | Flange inner diameter B1 | Socket | Flange neck big end N | Flange height H | Theoretical weight Kg | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | Bolt hole center circle diameter K | Bold hole diameter L | Bolt hole Quantity n(pieces) | B2 | U | ||||||||||

| 15 | ½ | 21.3 | 120 | 120.6 | 82.6 | 22 | 22.3 | 4 | 22.3 | &/8211; | 22.5 | 22.4 | 10 | 38 | 32 | 1.8 |

| 20 | ¾ | 26.9 | 130 | 130 | 88.9 | 22 | 22.3 | 4 | 25.4 | &/8211; | 27.5 | 27.7 | 11 | 44 | 35 | 2.41 |

| 25 | 1 | 33.7 | 150 | 149.3 | 101.6 | 26 | 25.4 | 4 | 28.6 | &/8211; | 34.5 | 34.5 | 13 | 52 | 41 | 3.55 |

| 32 | 1¼ | 42.4 | 160 | 158.7 | 111.1 | 26 | 25.4 | 4 | 28.6 | &/8211; | 43.5 | 43.2 | 14 | 64 | 41 | 4.02 |

| 40 | 1½ | 48.3 | 180 | 177.8 | 123.8 | 30 | 28.4 | 4 | 31.8 | &/8211; | 49.5 | 49.5 | 16 | 70 | 44 | 5.45 |

| 50 | 2 | 60.3 | 215 | 215.9 | 165.1 | 26 | 25.4 | 8 | 38.1 | &/8211; | 61.5 | 62 | 17 | 105 | 57 | 10.2 |

| 65 | 2½ | 76.1 | 245 | 244.3 | 190.5 | 30 | 28.4 | 8 | 41.3 | &/8211; | 77.6 | 74.7 | 19 | 124 | 64 | 13.9 |

Часто задаваемые вопросы (FAQ)

What are the ideal applications for socket weld flanges?

Socket weld flanges are best suited for small-size, high-pressure piping systems that do not handle highly corrosive fluids due to potential corrosion in the gap area.

How does the static and fatigue strength of socket weld flanges compare to other flanges?

Socket weld flanges offer similar static strength to slip-on flanges but have higher fatigue strength due to the single fillet weld, which enhances durability under fluctuating loads.

What materials are available for socket weld flanges?

Our socket weld flanges come in a variety of materials, including 304, 304L, 316L stainless steels, and high-strength alloys like 2507 and 2205, catering to diverse application needs.