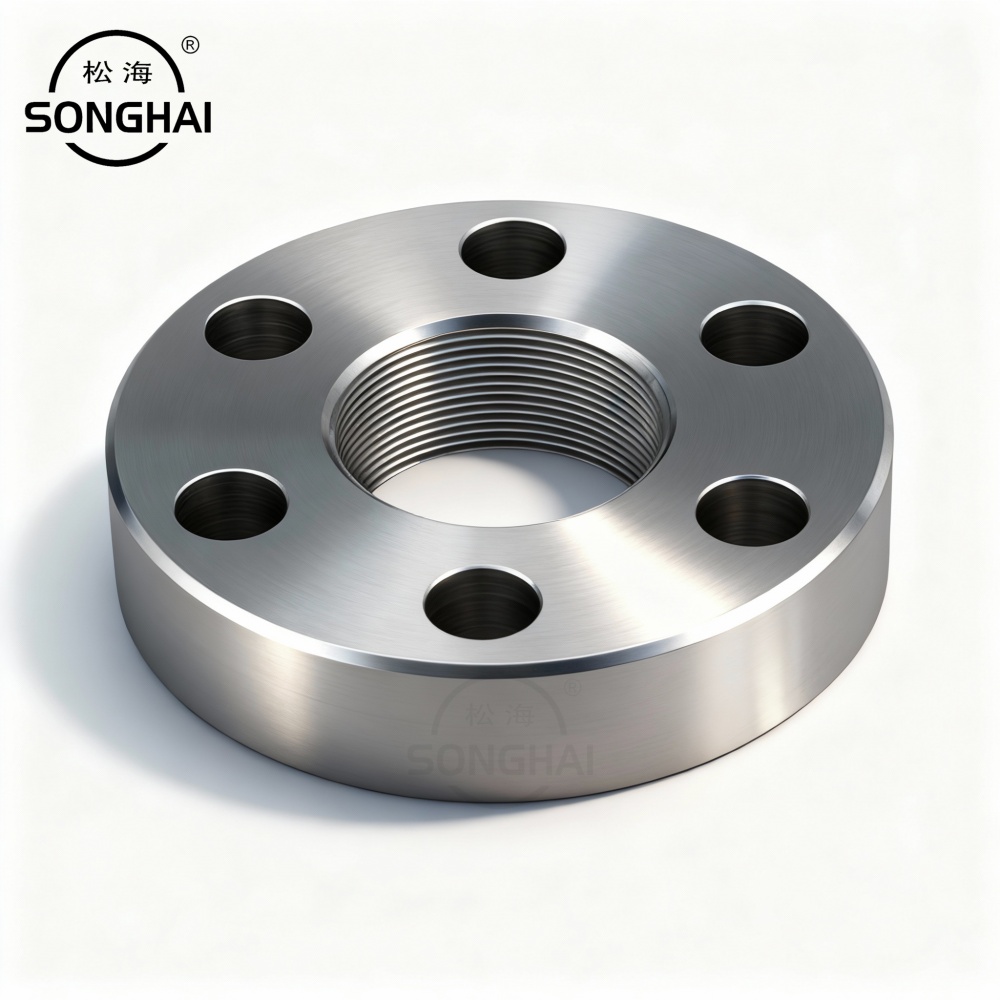

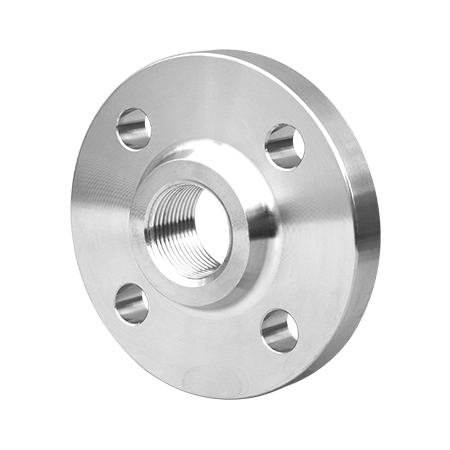

Резьбовые фланцы

Стандарты сертификации

With its internal pipe thread, it allows for easy assembly and disassembly without the need for welding.

This innovative design minimizes additional torque and deformation, ensuring a secure fit with minimal cost.

GB/T9119-2010

HG/T20592-2009

HG/T20615-2009

DIN

ASME

BS

JIS

Материал:

304:F304 S30408 S30408II S30408III S30400

304L:S30403 S30403II 30403 30403II

316L:31603 31603II 31603III

2507(F53)

2205(F51)

TP310S(06Cr5Ni20)

TP321(06Cr18Ni11)

S22053III=2205III

T321-32168=321

The threaded flange is a kind of non-welded flange that processes the inner hole of the flange into a pipe thread and is connected with a pipe with a thread. Compared with the flat welded flange or butt welded flange, the threaded flange has the characteristics of convenient installation and maintenance.For more information, please see the download section on the right.

Часто задаваемые вопросы (FAQ)

What are the advantages of using a threaded flange?

Threaded flanges offer convenient installation and maintenance, allowing for easy assembly and disassembly without welding, reducing additional torque and deformation.

When should I use threaded flanges?

Use a threaded flange when you need a non-welded, easy-to-install connection for pipes, especially in applications where frequent disassembly or maintenance is required, and welding is impractical. It is ideal for situations where reduced installation cost and simplicity are priorities.

How do I install a threaded flange?

To install a threaded flange: clean and align the flange with the pipe, thread it on by hand, tighten with a pipe wrench, check alignment, and apply sealant if needed.